Classification of cooling tower

This section talks about the type of cooling tower: Tower of natural convection and convection cooling towers mechanical applications in systems of industrial ice machine.

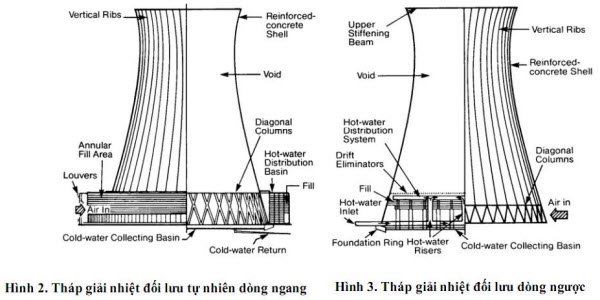

2.1. Natural convection cooling tower

Natural convection cooling tower or tower hypebol using the difference in temperature between the ambient air and hot air in the tower. When the hot air moves upward in the Tower (by hot air rising), cool new air goes into the Tower through the gas parts on the bottom of the tower. No need to use the fan and no rotation of hot air can affect performance thanks to the layout of the tower. The shell of the tower was mainly made of concrete, about 200 m. The cooling tower is usually only used for large heat demand because of large concrete structures is expensive.

There are two types of natural convection cooling tower:

-Tower horizontal line (fig. 2): the air is sucked along the water are falling and the buffer block placed outside the Tower

-reverse Pyramid (Figure 3): the air is sucked through the water are falling and the buffer block is placed in the Tower, though the design depends on the particular conditions

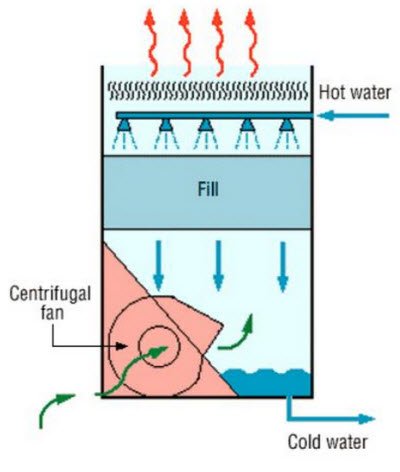

2.2. Mechanical convection cooling tower

Mechanical convection cooling tower has a large fan to suck the gas forced in water circulation. The water flows down on the surface of the block buffer, increasing the contact time between the water and air-helping maximize the process of heat transfer between water and air. The rate of cooling towers mechanical convection depends on a lot of different parameters such as fan diameter and operating speed, buffer block power back system.

Mechanical convection Towers currently available with very wide capacity range. The tower can be built in a factory or in the field-for example as the only concrete tower was built in the field. A lot of the tower to be built in a way that can work together to achieve the desired capacity. So a lot of cooling tower are connected from two separate towers, called "cell" cell number, v. d 8 Tower box is to just type this tower. Many turrets can box, square or round depending on the shape of the box and depending on the get gas to be placed on the side or bottom of the box.

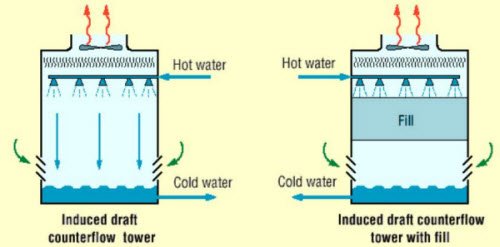

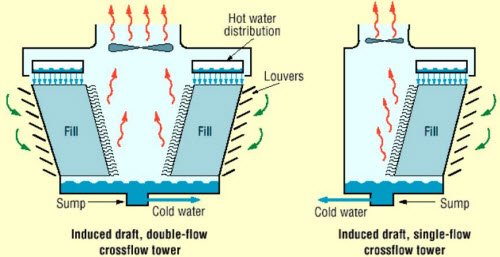

There are three types of mechanical convection towers as summarized in table 1.

Table 1. The main characteristics or types of cooling tower (under the AIRAH)

| Type of cooling tower | Advantages | The downside |

Forced convection cooling towers (Figure 4): The air is sucked into the Tower thanks to the fans for the gas to | Appropriate to be high gas thanks to fanning. The relatively noisy fan | Circulation thanks to the speed of gas into the gas velocity and high output low, can be solved by placing the Tower in the Chamber of the Assembly line along with the exhaust pipe |

Cooling tower air horizontal line (Figure 5): The water goes into the above and go through the block buffer. The air come in from one side (the Tower of a line) or from the opposite side (Tower two) A fan get gas into the buffer blocks go up through the exit at the top of the Tower | Less than the circulation of forced convection towers because more gas racao gas speed on from 3-4 times | Fan and motor controller needs against the conditions of the weather, humidity and corrosion because they put in wet gas line out |

Cooling tower air upstream (Figure 6): The hot water goes in the upper part. The air goes to the bottom and out at the top. Use the exhaust fan and a fan of pushing |

Figure 4. Forced convection cooling tower

Figure 5. Upstream convection cooling tower

Figure 6. The convection of horizontal flow cooling tower

(Collectibles-ice machines Ice Machines-industrial park)