Texture and materials of cold storage

Cold storage is a very important device in the book sewing systems industry. An introduce to our customers information about the structure and the materials needed to create a standard cold storage.

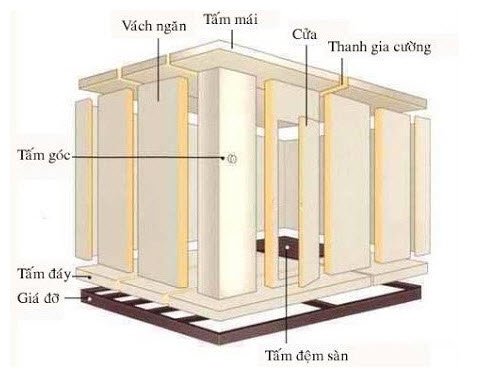

Standard cold storage structure

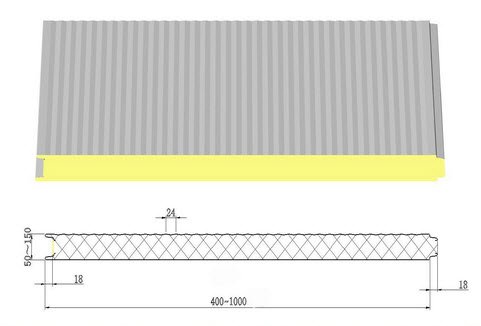

1. Cold storage panels

Panels are used with the following advantages:

+ Very good insulating ability and durability: insulation Core made of polyurethane insulation capable of extremely good and cold not disconnected at all temperature levels. Thanks to the temperature and humidity are always maintain stability so the food in cold storage has always been preserved very well and keep the quality.

+ Essential aesthetic and hygienic features: surface panels are composed of colored steel plate and stainless steel should be durability and aesthetics, product help users easily hygiene, cleaning and maintenance, and keep cold always ensure to food hygiene always be preserved the best.

+ Installation and moving fast: very easy panel mounting Plate or relocate therefore helps to shorten the time of installation or relocation is also very easily and quickly. Therefore to meet the customer's needs quickly.

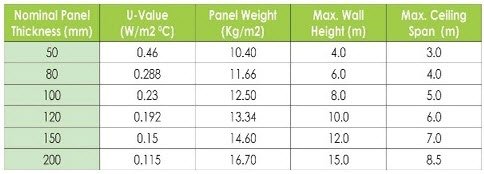

The specifications of standard panels:

Panel's specifications

2. Compressor cold storage cluster

-Refrigeration compressors have many different types such as: compressor model Ga-Scroll type compressors, compressors, Piston check.

-Refrigeration compressors have many different brands: Bitzer, Copeland, Carrier, Panasonic, Mitsubishi, LG, Grasso … depending on the needs of the client to choose the suitable compressor type and the highest efficiency.

-Refrigeration compressors are usually mounted on the concrete pad firmly fit each machine to ensure the machine is running smoothly, avoid getting wet when your rig and sanitation designed to air do not influence the sound, shaking out the surroundings. For small machines can be mounted on the frame rail or directly on the condenser form 12 blocks.

-Issues to be noted: the compressor installation operation operation, safety checks, easy maintenance, when the need to scrap are convenient and easy, pipe repair, construction, ventilation and most favorable lighting.

Cold compressor

3. A fan of cold

-Fan creates a fresh atmosphere, helps prevent dust, smoke odors, prevent loss of cold, save on energy costs, extend the life of your air conditioning because air conditioning is not continuous operations to offset the energy losses when closing the door.

A fan of cold

4. Cold storage manufacturing doors

-Cold storage manufacturing Door is designed with a protective coating with a heat resistant alloys and durability in wet environment. In addition to this protective layer can withstand huge forces.

-Cold storage manufacturing Doors are designed to have the ability to prevent loss of cold outside, make sure the temperature in cold storage has always been to maintain a stable temperature and good food inside cold be preserved the best

-In addition door cold must have the safety key and have the latch inside the can to close the opening from inside increased safety when someone on in storehouse.

Cold storage manufacturing doors

The above is the most basic information about cold storage. You can contact directly with An to get information more detailed advice. An adequate supply of all components of the system may da vien essential khiet.

Hotline: 09 49 41 41 41 (Mr. Hoan)