Learn about cooling tower systems in ice machines

Cooling tower is a device used to reduce the temperature of the water by extracting heat from water and atmospheric emissions. Take advantage of the cooling tower evaporation so that the water was evaporating into the air and atmospheric emissions. As a result, the remaining water is cooled significantly.

Cooling tower can reduce the temperature of the water is lower than the equipment only use air to remove heat as radiators of cars, the system may blue skin, so use the cooling tower to bring higher efficiency in terms of energy and costs.

The schema of a cooling water system

The parts of the cooling tower

The main parts of a cooling tower includes a frame and body of the tower blocks, mats, hot water, water, and gas shield on the door, the air hoses and fan. These parts are described below.

The frame and body of the tower. Most of the tower with structural frame help support for the outer hull (relative), engines, propellers and other parts. In the smaller design, such as the equipment made of glass fiber, the body of the Tower may be the frame always.

The frame and body cooling tower

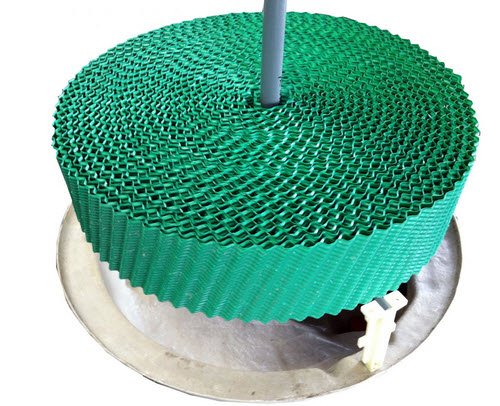

Buffer block. Most of the towers are buffer blocks (made of plastic or wood) to support the exchange of heat thanks to maximize contact between water and air. There are two types of block buffers:

Buffer Block-shape spray: water fall on the horizontal bar and row shot toé into drops reminding more than at the same time wetting the surface of the block buffer. Plastic spray-form buffer block help increase the heat better than the wooden buffer block.

Radiator panels (filling cooling tower)

-Buffer Block the membrane: thin plastic sheets covering the most recent survey, the water will fall on it, creating a thin layer in contact with the air. This surface may be flat, wrinkled, honeycomb or other types. This type of buffer blocks of membranes more effectively and create the exchange rates similar to the small traffic nhit than buffer block spray form.

The cold water tank. The cold water tank is placed near or right at the base of the Tower, the hot water flowing down through cool getting buffer blocks in the tower. Hot water collectors parts often have one or a sunken points to connect the discharge of cold water. With so many set statements towers, hot, cold water is placed just below the block buffer. However, in the upstream convection design, water in the bottom of the block buffer is connected to mộtvành the belt acts as hot cold water. Exhaust fan be fitted under the cushion to block air intake from the bottom up. With this design, the tower was more fitting the foot, helping to ease mounting the fan and motor.

Water shield. This equipment collects the drops of water trapped in the air line, otherwise they will be lost to the atmosphere.

Gas parts on. This is the parts get gas into the tower. This Department can occupy the whole of one side of the Tower (the horizontal flow design) or put the bottom of one side or the bottom of the Tower (reverse-flow design).

The door on the air. Usually, the horizontal line towers have taken the gas on. The purpose of this is to balance the air flow into the buffer blocks and retaining water in the tower. A lot of the design of the Tower need not take door gas upstream.

Fire sprinklers. Sprinklers to wet block buffer. Uniform water distribution in the upper part of the block buffers are needed to achieve the wet surface of the block buffer. The hose can be fixed or spray according to square or circle, or a can is a division of rotational lines as is common in a number of horizontal convection heat giảin Tower.

Fan. All axial fans (fans pushing) and centrifugal fans are used in the tower. Usually the fan pushes be used in ventilation and both the fan and the centrifugal push are used for forced ventilation in the tower. Depending on the size, can use the pusher propeller, fixed or variable wing tilt. Fan with adjustable tilt-wing does not automatically be used in wide range of kW because fans can be adjusted to the desired air flow rotation in the lowest energy consumption. Automatic change swept wings can replace odỏi air flow under load conditions change.

(Collection-blue leather Sewing book)